Floating contact elements from our SMD and THR products reliably compensate for thermal deformations at widely varying temperatures, among other things.

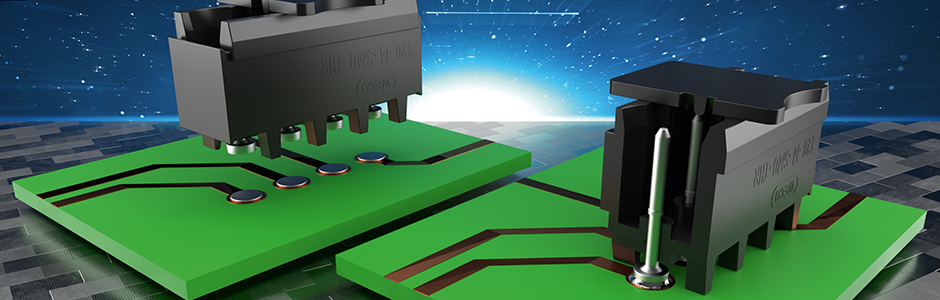

With the SMarTconn product range, WECO offers a large selection of PCB connectors and pin headers for automated SMD assembly.

A key challenge with this type of assembly has always been the coplanarity and strength of the components. This is where WECO has developed its “floating elements”: sockets, pin headers and anchors that are movably mounted in the housing. In addition to the standard SMD products, there are also special variants with these “floating” contact elements.

Products with special elements offer significant advantages for customers:

Compensation of bended printed circuit boards.

Compensation for unevenness in solder pads

Compensation of thermal deformations of the housing due to changes in temperature.

Significant reduction of component stresses directly in live operation.

Lateral flanges additionally increase stability and the pull-off forces for pin strips.

Movable terminal bodies or "Floating terminal bodies"

The geometric characteristics of the terminal body – or “floating terminal body” – provide sufficient space for the solder paste and also ensure good heat circulation for a flawless soldering process and visual solder joint inspection.

Products with “floating terminal body”:

930-A-SMD-DS

3.5 mm

950-D-SMD-DS

5.0 mm

974-D-SMD-DS

5.0 mm

Movable pins or "Floating pins"

With pin headers, the individually mounted pins also ensure a perfect fit on the PCB. In addition, the pins can center themselves in the solder pad during the soldering process due to the simple physical process of natural cohesion. In this way, the grid remains intact despite moving pins.

Products with “floating pins”:

110-M-221-SMD

3.5 mm

110-M-226-SMD

3.5 mm

120-M-221-SMD

5.0 mm

120-M-227-SMD

5.0 mm

Movable anchors or "Floating Anchors"

The “floating anchors” are additional elements to absorb any push, pull and shear forces that occur. They are mounted in lateral flanges and therefore the connector or pin header requires a little more space on the PCB. The anchors are slightly offset to the front in relation to the center of the terminal to allow the holding force to act where the conductors are connected. This ensures that the force applied to the connection pins is significantly reduced.

The anchors of the 110-M-216-SMD pin header, for example, can withstand loads of 65 N and optimally absorb the shear forces that occur. The soldering points of the contacts are less stressed and the forces on the individual soldering points are reduced.

Products with “Floating Anchor”:

110-M-216-SMD

3.5 mm

110-M-226-SMD

3.5 mm

210-A-126-SMD

3.5 mm

140-A-126-SMD

5.0 mm

“Our customers appreciate the proven floating pin technology because it ensures absolute coplanarity of the contact surfaces to the PCB,” explains Detlef Fritsch, Managing Director of our WECO branch in Germany.

Every product in our SMD and THR series has been subjected to extensive peel and pull-off tests. Provided the soldering is perfect, the retention forces are comparable to conventional PCB terminals.

Our solutions sit perfectly on the solder pads and do not cause stress on the PCB.

Board deformations are compensated for and the optimal surface contact achieved results in a low transmission loss.

Further Information

We have sparked your interest and you would like to find out more?

Just get in touch with us!

Use our contact form or send us an e-mail to [email protected].