WECO drove solutions on the road to Development

Dear Colleagues,

The 1940s was probably one of the most important decades of the last century. The war and the technology that followed changed people’s lives on a massive scale. In that decade, the primary inventions were the first successful mass-produced turboprop engines and the world’s first fully automatic programmable digital computer – the “Z3” computers. As part of a government project, Konrad Zuse built the Z3, the natural evolution of his original and rather limited Z1. The Z3 was also the first computer-controlled by software.

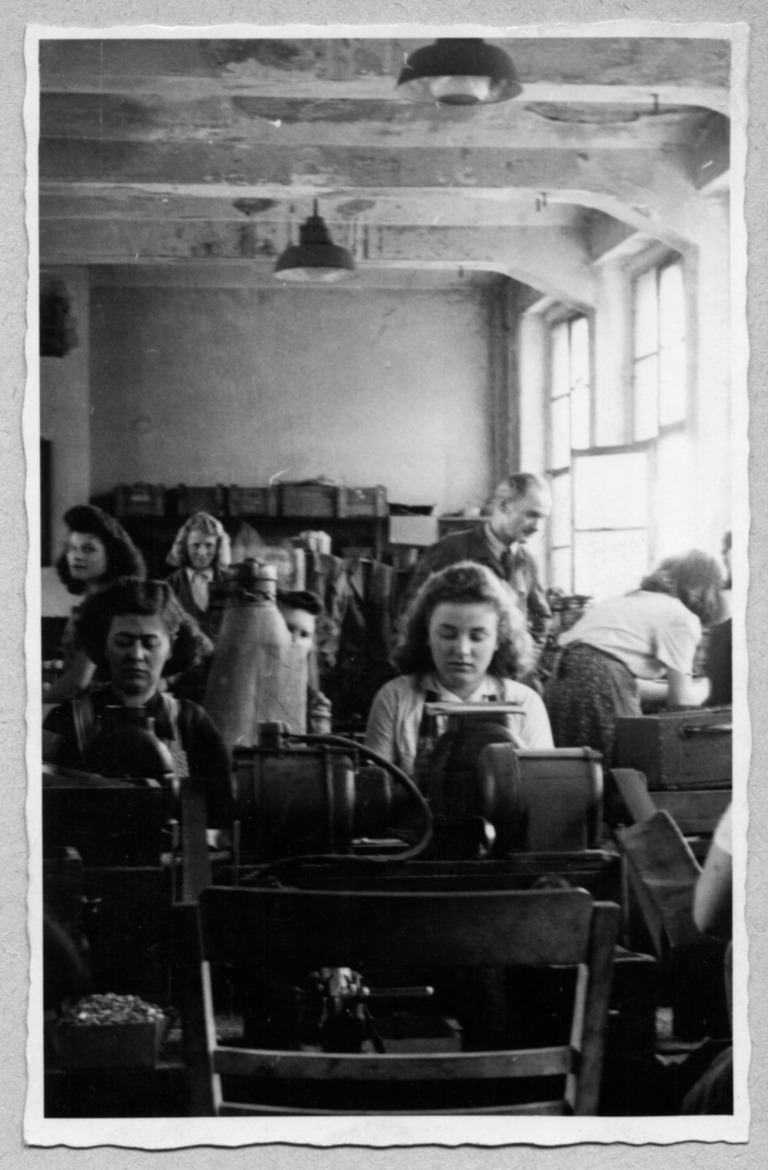

In the same decade, more precisely in 1943, WECO’s production moved from Hanau to Bruchköbel. Looking back, this decision proved to be the right choice, as the original production facility in Hanau was destroyed in 1945. WECO immediately began its reconstruction; a newer, larger facility to accommodate its growing workforce, now counting some 90 employees and capable of meeting the rising market demand. This speaks for WECO’s unwavering entrepreneurial spirit.

![Email#4---1951---Messestand-HannoverMesse-[APP01]](https://wecoconnectors.com/wp-content/uploads/2021/12/Email4-1951-Messestand-HannoverMesse-APP01.jpg)

In the mid 1940s, WECO managed to start a unique triumphal procession that resulted in a new patent; a new connector with insulating bodies made of thermoplastic material. This material allowed the company to offer new products that were unfeasible with the former insulating bodies made exclusively of porcelain or bakelite. This improvement to the original terminals used in the lighting industry was initially coined “Lüsterklemmen” or in French “lustre” meaning chandelier and was the precursor to the present-day Euro Style connectors. It made a big impact and was the “Top-Seller” at the very first trade show.

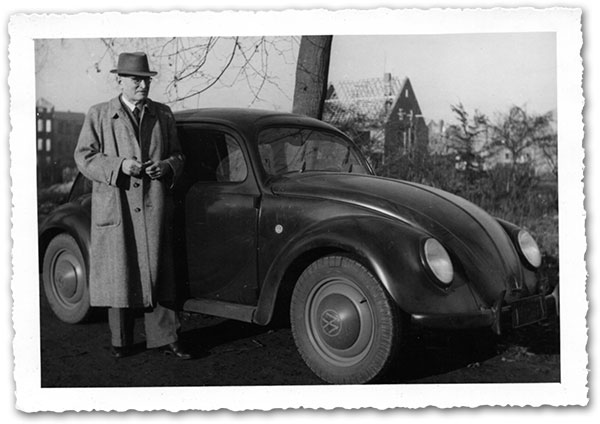

WECO entered the automotive market during the time when the automotive industry began to take over the market with the Volkswagen “VW Beetle” – the first car for the general public, as it was affordable for the average consumer. With the new patented thermoplastics, WECO worked diligently on solutions for this new market, and designed a plug coupling used to connect electrical wires between the vehicle and the trailer. This was the prelude to the use of plug-in connections capable of withstanding harsh environmental conditions and strong vibrations. Other products for the transportation and automotive sectors followed. These products paved the way for WECO’s entry into the new automotive and transportation markets!

Although they have been enhanced over time, many of the connecting elements developed at that time are still in use today, and the success of these proven products has opened up new markets. Ceramic connectors with mantle terminals found their way into the shipping industry and are still used in the construction of new container ships due to their robustness and proven reliability.

WECO’s introduction of PCB terminals has expanded to new areas of application in the automotive industry and in other segments of the transportation industry. Today, the focus is not only on robustness and resistance to vibrations, but also on fast and easy assembly and ease of maintenance. Our plug-in connections, which are sufficiently robust for use in dump trucks, are equally reliable and used in radio remote controls for crane systems.

WECO did not rest on its laurels, and patented SMarTconn, with its floating pin technology. These connectors opened new areas in the automotive market, and WECO made further inroads with applications in automatic transmission – a market segment that represents a decisive step into the future and which secures our brand.

Next week you will learn how WECO successfully innovated industrial automation and met the challenges of the next decade. Stay tuned.

Sincerely,

WECO Team