WECO supported the new communication media

After the strong baby boom in the previous decade, the technical developments in communication made televisions and telephones everyday items to have in the home! Its use expanded exponentially, and industry began using the first digital transmission media such as fax machines and electronic typewriters.

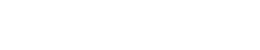

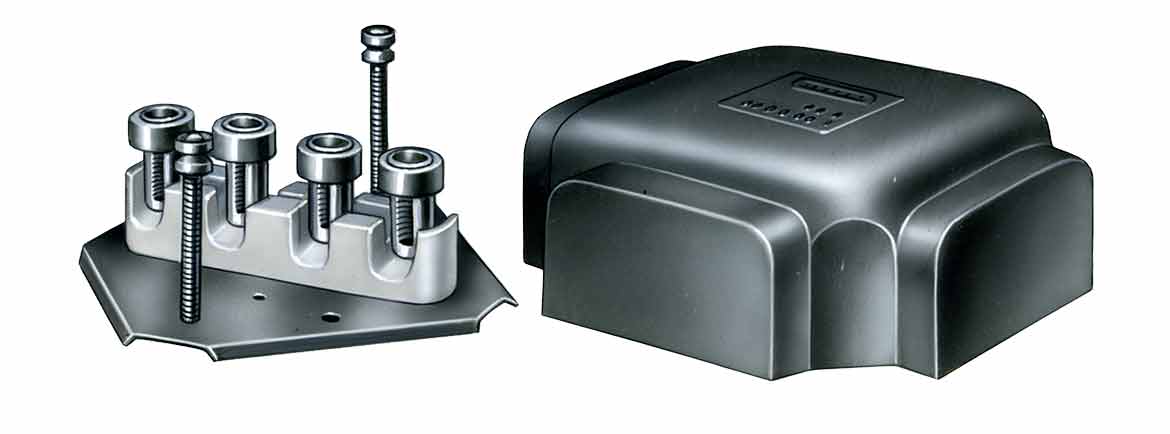

Switch board operators physically transferred the call from one line to the next using a series of plug-in cables. To allow the functioning of the large switchboards, there needed to be a mechanism to distribute power. WECO provided an initial variation to the screw barrier strip. Originally made from backelite, the screw terminals took off as each of these new means of communication were using a base component called a printed circuit board which allowed multiple signals and power to be distributed.

Communication became yet another new market for WECO resulting in the development of new products designed with PCB terminals. During this period WECO’s product line expanded to 15 new connector-families including the development of a new series of “flat” later called MINIFFLEX KUPPLUNG or coupling.

With a new market to service and an expanding product line, WECO saw its workforce grow to over 150 employees. Not only did the communication market broaden WECO’s product line, but it also allowed WECO to set up its internal tool shop to support the need to manufacture production dies and manufacture connectors.

In 1965, WECO invested in its facility, first with the expansion of the factory by purchasing of the adjacent property in downtown Hanau and second with the purchase of a plastic injection moulding machine followed by an additional four. These were giant leaps towards expanding the product range with new moulded plastic housings and the ability to quickly react to customer demands, a first step in WECO’s agility. From this point on, PCB terminals could be manufacture entirely in-house, which not only satisfied the increasing market demand, but also made WECO a stronger partner for customers in the electronics industry.

Dr. Walter Ebbinghaus, the grandson of the founder managed the company through this period and played a decisive role in expanding WECO’s success for the next 29 years. The rapid progress in the economy also made itself felt in the wage sector. Rising wages not only benefited the employee, but it was also the basis for a consumer and affluent society, which in turn benefited the companies, including WECO. To give you an idea of local wages at WECO in this time period, look over the salary scale and judge for yourself how it compares to your present day pay check!

1948: DM 1,10/h (for skilled workers)

1954: DM 0,75/h (for unskilled workers)

1969: DM 3,86/h (for skilled workers).

Over the years, WECO’s products migrated to newer communication platforms, from POTS (Plain Old Telephone Systems) to present day mobile phones where our connectors are used to power the cell tower transmitters and powering broadcast equipment. The need for innovative connection solutions have flourished as the requirement for space-saving solutions became even more essential in order to maximize PCB real estate. Surface mounted technology (SMT) is not only required to save space for signal connectors with low current, but equally important for power terminal blocks to supply power at a higher current. Today, WECO has a complete line of SmarTconn family of connectors to service this market.

Next week you will learn how WECO managed to enter a new market segment comprising heating, ventilation and air-conditioning systems, and met the challenges of the new decade. Stay tuned.