Home » Support

WECO SUPPORT

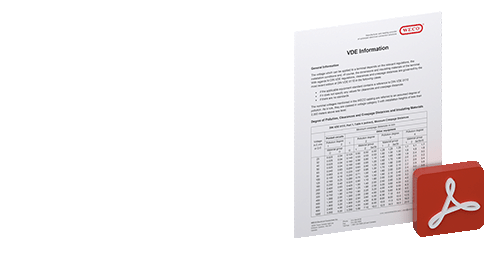

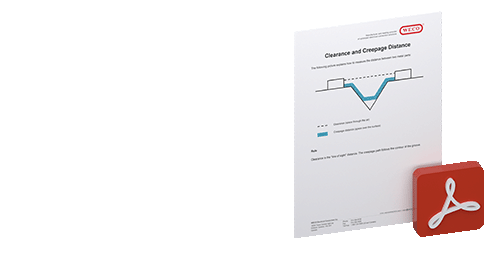

VDE ratings are outlined based on degree of pollution, clearances, creepage distances and insulating materials.