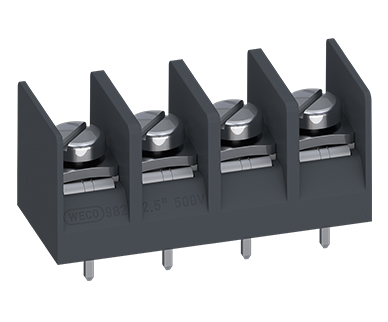

WECO connectors maximize the reliability of industrial or home appliances, facilitate user safety, and allow clients to design products with a longer mean time between failures.

Instrumentation devices such as detectors, sensors, monitors, and fuel pumps require components that are more resistant to extreme temperatures, humidity, corrosion, and vibration: rely on WECO’s robust connectors for these applications.

Industrial Appliances and Instrumentation Sector

Electrical Connector Solutions

CNC

WECO has designed power connectors that withstand the demands of CNC machinery; vibration, harsh environments, and high temperatures allowing the computer-controlled manufacturing tools, including lathes, mills, routers, and grinders to perform repeatability with precision, and speed.

POS Devices

WECO connectors can be integrated into a variety of Automated Teller Machine (ATM) components, such as keypads, card scanners, and display screens.

Our solutions are both durable and dependable, helping our clients minimize downtime and achieve peace of mind.

Tankless Water Heaters

WECO’s connectors allow tankless water heaters to continuously provide hot water while minimizing your long-term cost of ownership.

As tankless heaters help regulate the amount of water that is used to heat a given building, WECO’s high-quality, resistant, and long-lasting connectors are the perfect solution to ensure continuous power connections

Flow Meters

Flow meters are available in a variety of technologies – such as ultrasonic flow meters and mass flow meters – they measure the movement of fluids.

WECO’s compact power connectors have paved the way for OEMs to make their meters more intelligent and networkable, with features that can increase productivity for factories and utilities.

Fuel Distribution

Fuel management tools are responsible for essential residential, commercial, and industrial monitoring tasks.

From fuel line leak detection to fuel tank gauges and meter registers, WECO’s high-performance electrical connectors are designed to maximize your fuel management equipment’s efficiency, allowing you to provide essential data and information to your customers.